Research Highlight 3 - Adhesives from Waste Baby Diapers

- Sini Nalakathu Kolanadiyil

- May 31, 2022

- 2 min read

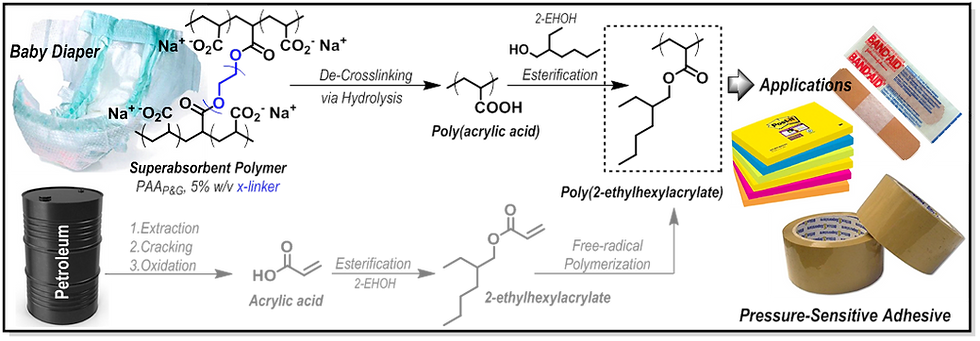

Researchers from the University of Michigan, Prof. Anne J. McNeil and colleagues have recently upcycled baby diapers into a pressure sensitive adhesive, commonly used in office tapes, bandages, sticky notes, removable labels, and so on – which has an expected $13 billion global market by 2023. The superabsorbent crosslinked polymer in diapers – namely a sodium poly(acrylate) crosslinked with ~0.05 mol% of poly(ethylene glycol), was converted into a thermoplastic adhesive – poly(2-ethylhexylacrylate) via open-loop chemical recycling process – a term used for upcycling of polymer waste into a high value material in order to expand their lifetime. The work is published in the journal ‘Nature Communications’[1].